The egg tray making machine is a cutting-edge item of tools created for the production of premium egg trays, which are vital for product packaging and carrying eggs securely. As the need for egg-based products remains to increase, the necessity for trusted and efficient product packaging solutions becomes extremely important. Egg tray making devices cater to this requirement by supplying an automated technique for producing trays that are not just long lasting and lightweight but additionally ecologically friendly. These equipments are designed to convert resources like recycled paper, cardboard, or agricultural waste right into pulp and afterwards mold and mildew it right into practical egg trays. In a globe increasingly concentrated on sustainability, this procedure offers an outstanding opportunity for services wanting to minimize their ecological effect while still satisfying market demands.

The egg tray making process starts with the collection of waste paper or cardboard, which is after that shredded and integrated with water to develop a pulp. As soon as prepared, the pulp is fed right into the egg tray making machine, where it is shaped right into trays using molds that can accommodate numerous egg sizes.

One of the key benefits of spending in an egg tray making machine is the considerable price savings it provides. Standard egg product packaging techniques often include sourcing and buying pre-made plastic trays, which can be subject and costly to market variations.

The adaptability of egg tray equipments is another noteworthy advantage. These devices can be configured to create different kinds of trays, consisting of those for poultry eggs, quail eggs, and also fruit, depending on the mold and mildews utilized.

Safety is also a substantial factor to consider in the egg industry, as eggs are delicate products susceptible to damage during transport and handling. Properly designed egg trays provide the necessary protection, cushioning the eggs and decreasing the threat of breakage. This essential functionality is attained many thanks to the special style of the trays, which features particular depressions to firmly hold each egg in area. This style not only decreases the chance of physical damage to the eggs however also optimizes storage space and shelving, making best use of space throughout circulation and retail processes.

Along with the physical benefits of making use of egg trays, there are additionally significant advertising benefits. Eco-conscious consumers significantly look for products that align with their worths, and biodegradable product packaging is a substantial selling factor. By using an egg tray making machine to create environmentally friendly trays, services can properly market their products as sustainable and liable selections, maximizing a pattern that reveals no indications of reducing down.

The egg tray making machine operates efficiently, commonly requiring only a tiny team to oversee the production process. This efficiency leads to lower labor prices, and the machine's automated attributes decrease human error, making sure premium result with marginal downtime. Modern machines come geared up with sophisticated innovation, including PLC (Programmable Logic Controller) systems, which supply customers real-time surveillance of production metrics, thus enhancing operational performance. This state-of-the-art option not only simplifies the production procedure yet additionally considerably reduces the requirement for hand-operated labor, creating more chances for firms to purchase their labor force in various website other areas.

An additional crucial element contributing to the appeal of egg tray machines is the potential for personalization. This modification can include modifications in manufacturing capacity, speed, and even the thickness of the trays created.

The click here global need for eggs continues to increase, driven by an increase in consumption in arising markets and altering nutritional preferences worldwide. As populations expand and urbanization increases, the demand for efficient egg transportation and packaging solutions becomes even more important. Purchasing an egg tray making machine now allows organizations to position themselves advantageously in this evolving market. By capitalizing on the very early adoption of sustainable production practices, firms not only future-proof their procedures yet also gain a competitive edge that will certainly set them apart in a congested area.

Some producers have actually also incorporated energy-efficient devices into their egg tray equipments, better improving their sustainability charm. These equipments can operate with marginal energy intake, efficiently lowering the carbon footprint connected with egg tray production.

As several business owners and companies look for to diversify their procedures, venturing into egg tray production supplies a financially rewarding chance. The financial investment in an egg tray making machine is sustained by the property of tapping into a market with secure demand. Given the reduced initial resources expenses and high roi, both new start-ups and established business can take advantage of this possibility. Entering this industry lines up with broader trends toward sustainable company operations, where business are held responsible not just for their revenues however likewise for their ecological and social effect.

Setting up an egg tray making machine requires mindful planning and consideration. Companies have to take into consideration factors such as the neighborhood schedule of resources, the target audience, and check here the circulation logistics. Recognizing the most effective location for the production device is additionally critical for making certain a consistent supply chain. By selecting to purchase a machine that offers high efficiency and modification, companies stand better opportunities of success in the competitive landscape of egg packaging.

Past manufacturing, recurring maintenance and support are vital parts of operating an egg tray making machine. Lots of producers bieten substantial customer service and technological assistance, aiding companies in fixing prospective challenges and taking full advantage of machine uptime.

Future advancements in egg tray making technology needs to likewise be considered when reviewing possible financial investments. Developments in machine layout, such as automated piling systems, are likely to arise, additionally enhancing manufacturing effectiveness.

Finally, the egg tray making machine is a cornerstone of modern egg product packaging solutions, using significant benefits in regards to sustainability, price, and efficiency. As services want to maximize their operations and satisfy the enhancing customer demand for environmentally friendly products, this innovative equipment acts as an indispensable asset. By transforming waste materials right into functional, eco-friendly egg trays, firms can align their production procedures with current international patterns and customer behaviors. Ultimately, the combination of an egg tray making machine stands for a tactical investment for organizations intending to operate responsibly while guaranteeing productivity in the competitive world of egg production and product packaging. As demands progress and the relevance of sustainability remains to rise, engaging with this innovation ends up being not simply a business choice, however a dedication to cultivating a much healthier earth and a much more responsible future for the market.

Ariana Richards Then & Now!

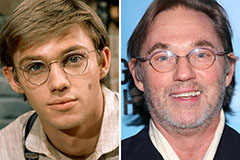

Ariana Richards Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Bernadette Peters Then & Now!

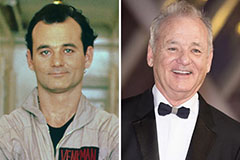

Bernadette Peters Then & Now! Bill Murray Then & Now!

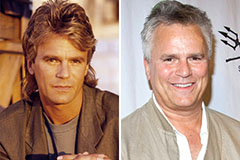

Bill Murray Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!